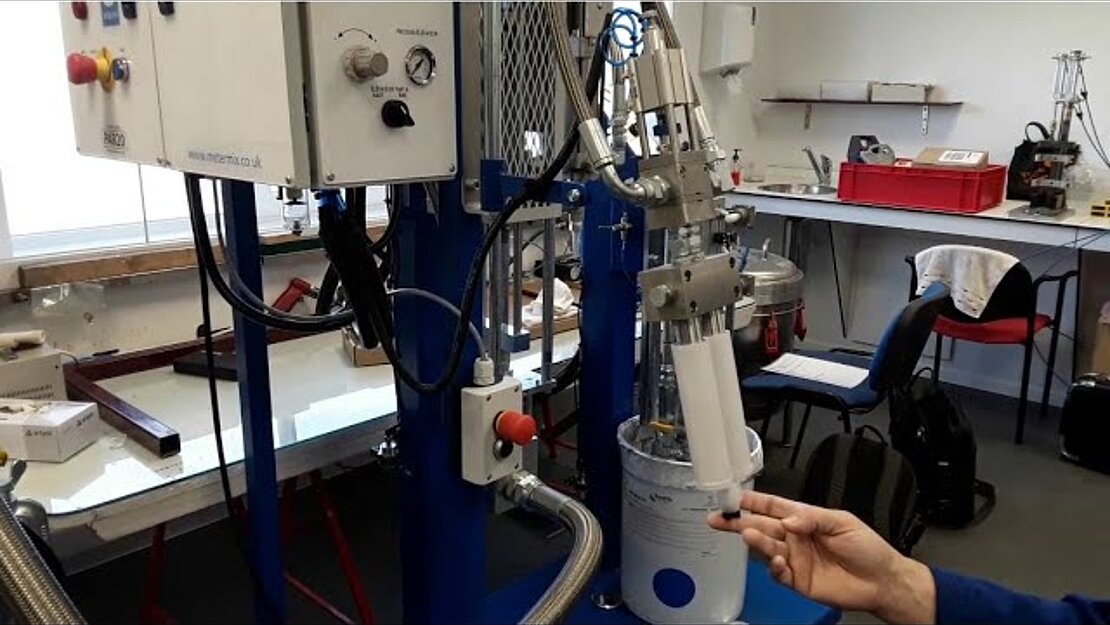

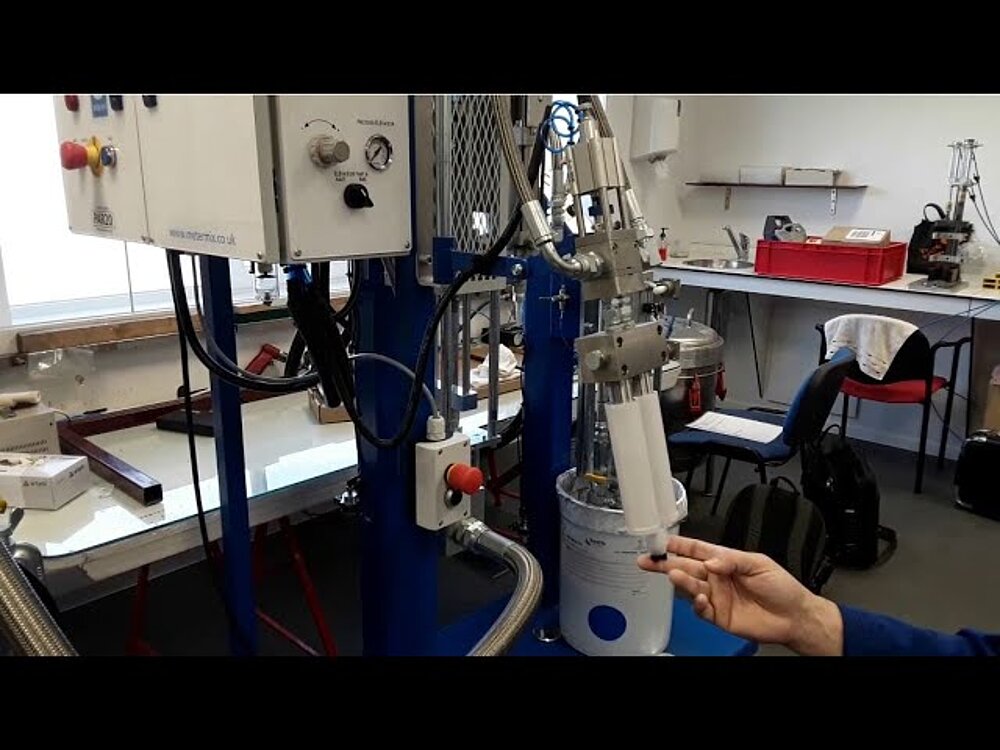

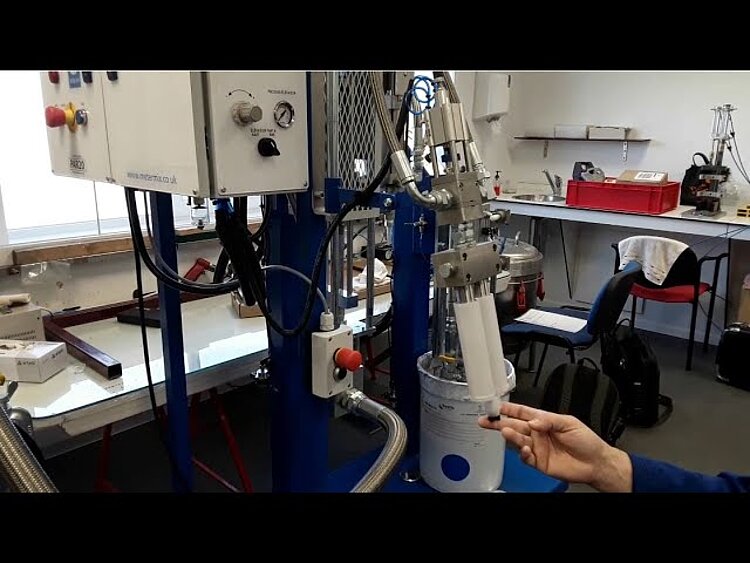

Flexible filling of cartridges with adhesives

Metering and mixing systems for one and two part materials offer flexible solutions

For manual adhesive applications, smaller cartridges or syringes need to be filled because one or two component adhesives will be provided often in large drums and are not easy to handle. With the PasteShot 20 metering and mixing machine, customers can fill cartridges or syringes very quickly and flexibly. The advantage: The customer can fill the cartridges or syringes in-house and are not reliant on an external filling company. Later, they could sell the cartridges or transport them to other production sites. It is an economical and efficient solution instead of manual metering and mixing. The PasteShot 20C machine ensures a reliable and reproducible production and a clean working process.

The PasteShot 20 machine can process a wide range of high-viscosity material systems. Based on the material, METER MIX® is able to make customized adjustments. The PasteShot 20 incorporates twin follower seal plates which allow both materials to be dispensed directly from the supplier’s containers. Furthermore, it is equipped with the latest METER MIX® ILD (in-line drive mechanism) for accurate and consistent processing of materials with high mix ratios or vastly differing viscosities.

Your advantages

- Small footprint

- Easy operation and maintenance

- Feasible investment costs

- Good value for money

- Reliable and reproducible metering and mixing

- Clean working process

Your benefits

•30 years of experience

•Easy to handle machines

•Short delivery times

•Suited to the needs of a wide range of applications

•Individual sales and service

•Presence in more than 40 countries